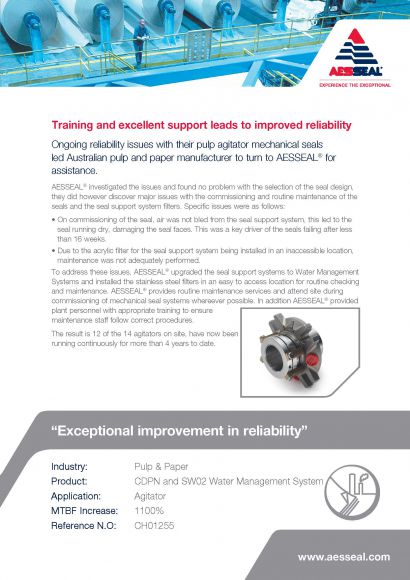

Ongoing reliability issues with their pulp agitator mechanical seals led Australian pulp and paper manufacturer to turn to AESSEAL® for assistance.

Case Studies

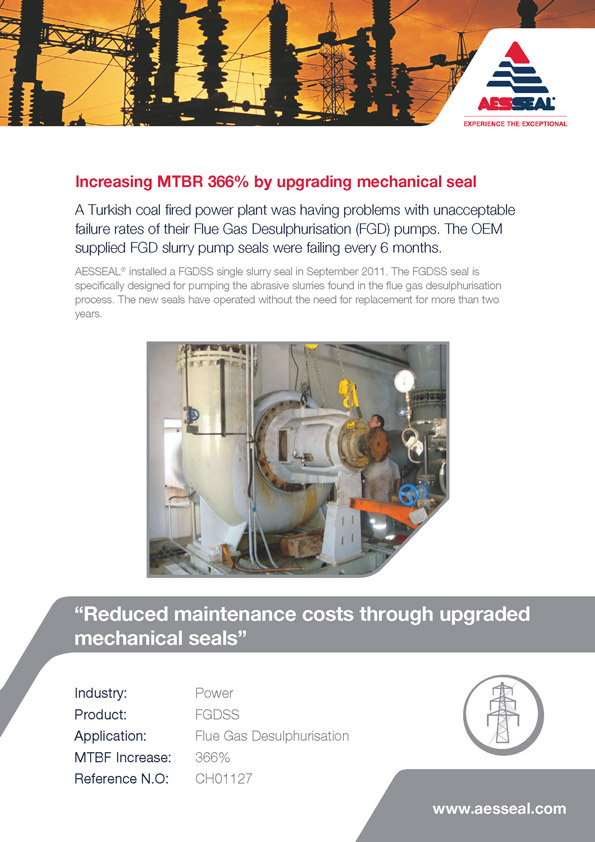

AESSEAL installed a FGDSS single slurry seal in September 2011. The FGDSS seal is specifically designed for pumping the abrasive slurries.

Case Studies

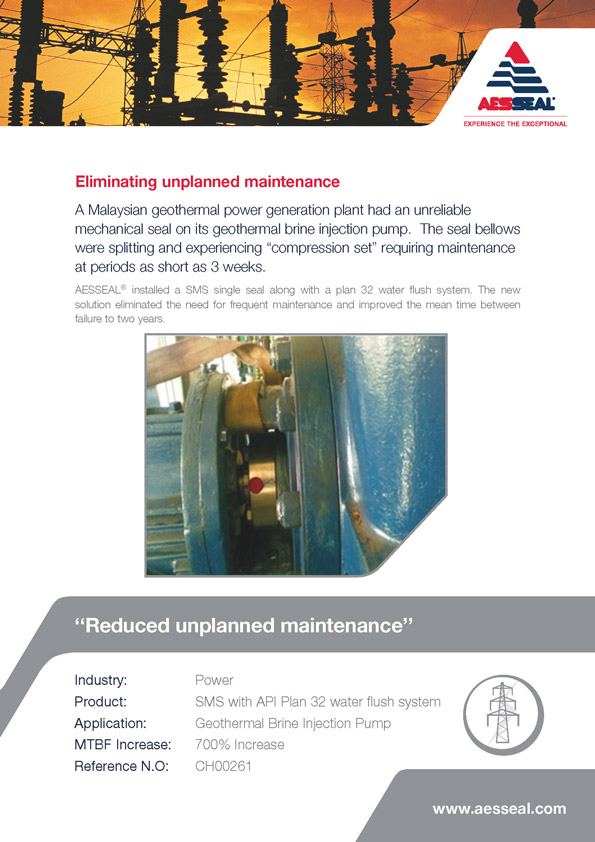

A Malaysian geothermal power generation plant had an unreliable mechanical seal on its geothermal brine injection pump. The new solution eliminated the need for frequent maintenance.

Case Studies

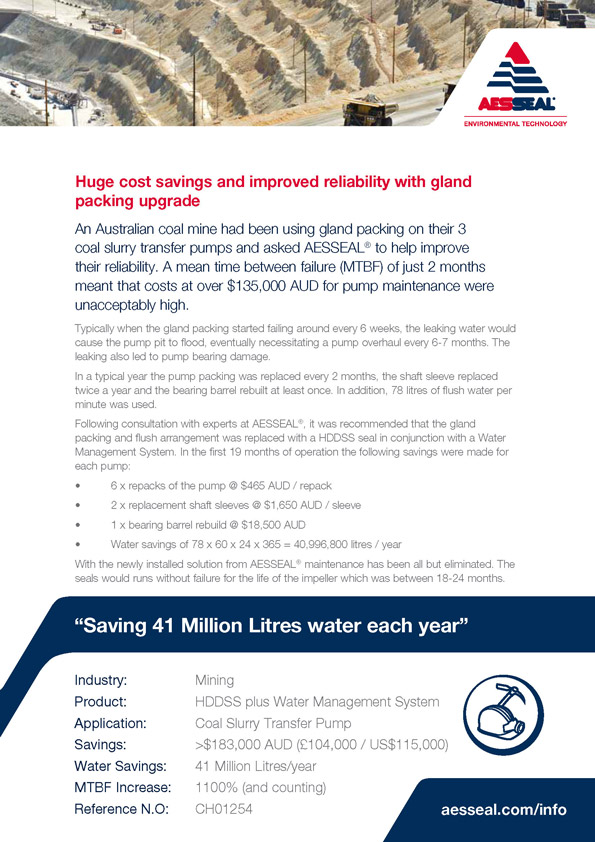

A mean time between failure (MTBF) of just 2 months meant that costs at over $135,000 AUD for pump maintenance were unacceptably high.

Case Studies

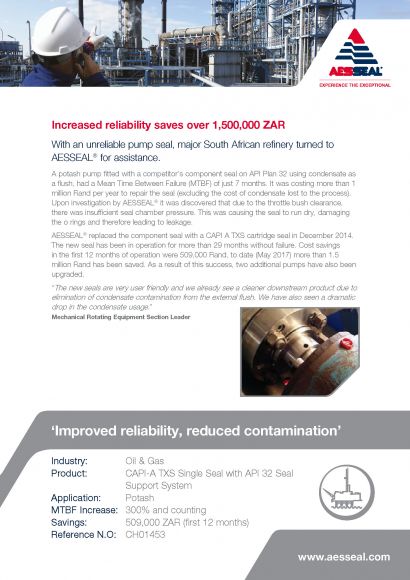

With an unreliable pump seal, major South African refinery turned to AESSEAL for assistance.

Case Studies

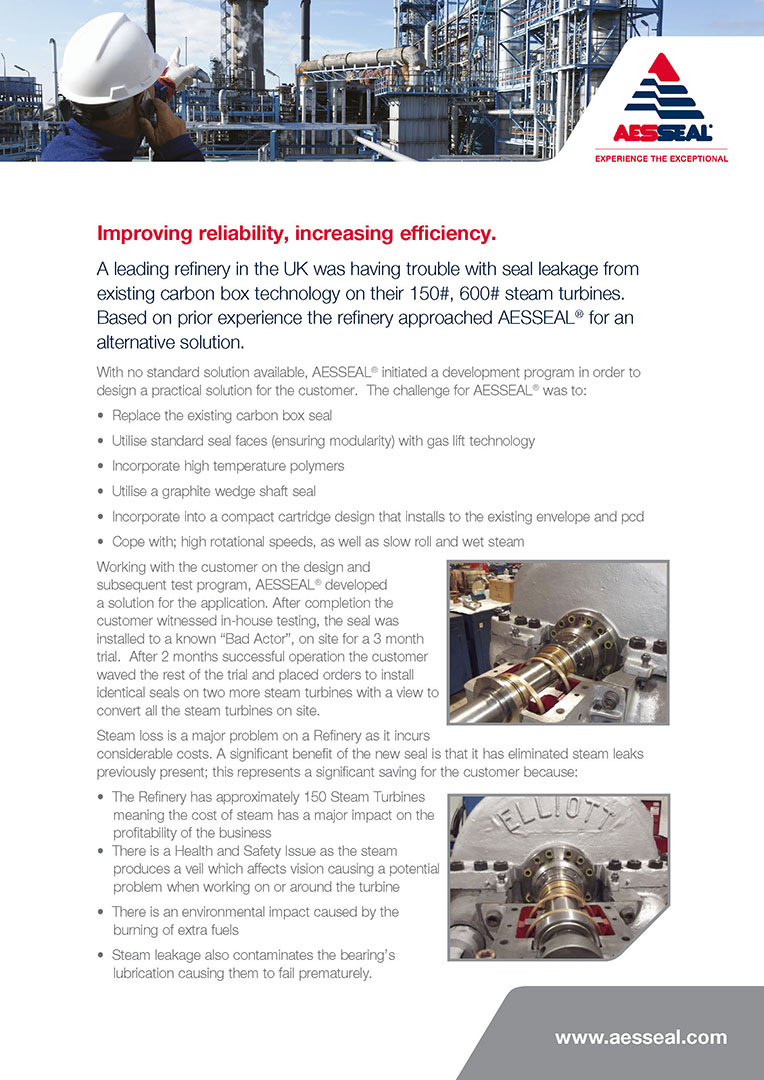

A leading refinery in the UK was having trouble with seal leakage from existing carbon box technology on their 150#, 600# steam turbines.

Case Studies

A UK based food processing plant was having major water ingress through the vertical shaft on their cold room gearbox.